Three Advantages of Bizen Chemical

Bizen Chemical can satisfy the needs of our customers by utilizing an integrated

production system

that covers everything from raw material procurement to commercialization.

-

Advantage

1Original technology leading to new value

-

Advantage

2R&D and manufacturing tailored to customer requirements

-

Advantage

3Integrated production system that meets strict quality standards

1

Original technology

leading to new value

Our Mission Creating new value by

using original technology

to support people’s health

Since Bizen Chemical was founded, we have never given up on our passion to create

products that improve people’s health. We have built up the capabilities to utilize natural materials

to create novel products and new value. Our active pursuit of research and development has given us the

power to achieve such goals.

Although it is no easy task to be a pioneer in the industry,

we have a

relentless drive to support people’s health, leading to a more fulfilling life for all. While highly

valuing the requirements of our customers, we strive to create original ideas and seek new horizons.

-

New

Value

1

Original Materials

Bizen Chemical harnesses the power of natural materials to create unique functional materials. We pursue novel forms of manufacturing to bring a wide range of products into reality.

Materials -

New

Value

2

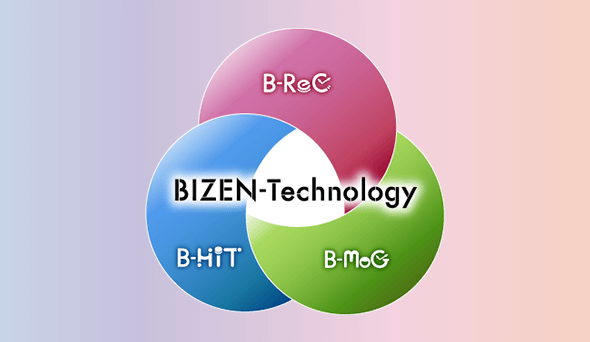

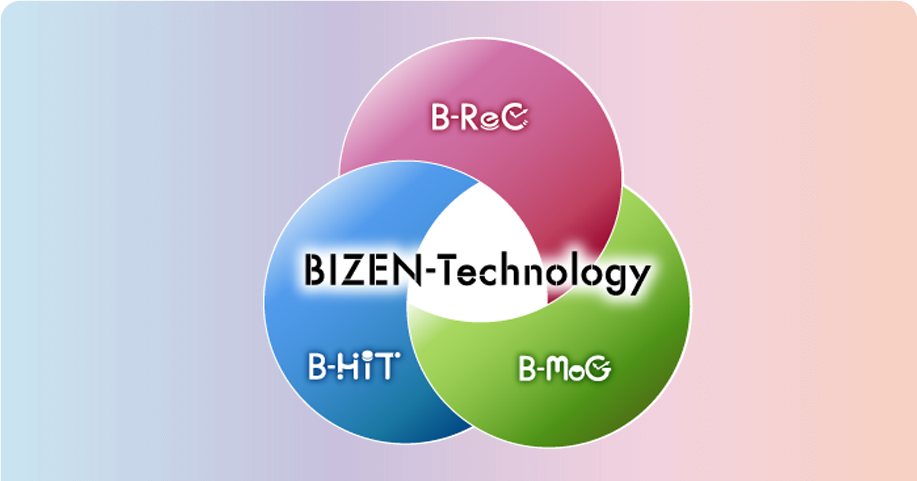

BIZEN-Technology

Bizen Chemical utilizes original formulation technology that maximizes the functions of the ingredients to provide high-value added supplements.

Our Technology

2

R&D and manufacturing

tailored to customer

requirements

We have the flexibility to respond to customer requirements from the research and development of functional materials to the development of formulations. In addition to providing comprehensive support from the development of materials to OEM production, we also research, develop, manufacture, and sell our own brand of functional materials.

- Raw Materials

- Planning & Design

- Material Development

- Oleo Fine Chemicals & Extracts

Material Development

Oleo Fine Chemicals

We successfully achieved the production of

high-concentration and high-purity

omega-3 fatty acids.

By combining our original extraction, chromatography, and distillation techniques, we are making strides in the research and development of high-concentration and high-purity formulations. We have had particular success producing omega-3 fatty acids, which are effective in maintaining good health or preventing and treating diseases, as well as lipids, which are traditionally difficult to produce with high concentrations and purity.

Extracts

We are striving to develop new beneficial functional materials and enrich the body of evidence in each field.

As part of our goal to create effective materials, we conduct research on a daily basis and actively test raw materials such as plants, agricultural products, and marine products for potential health benefits. We endeavor to carefully produce materials that help maintain and improve people’s health, and constantly work to create high-quality products that everyone can use with peace of mind.

- Planning & Design

- Tablet Formulation Development

- Final Product

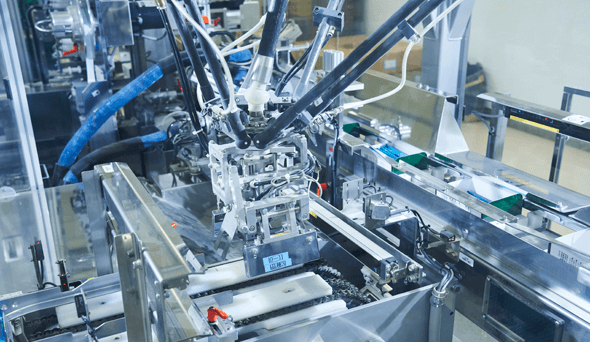

Tablet Formulation Development

Fully utilizing our B-ReC, B-MoG, and B-HiT technologies,

we create

suitable products with flavoring or by designing formulations

tailored to product

concepts.

We are constantly working to develop formulation technology and product proposals so we can continue to deliver products that meet the strict requirements and concepts of our customers. We design formulations, manufacture prototypes, and perform severe testing to find optimum conditions. This ensures that our products perfectly match customer expectations.

3

Integrated production system

that meets strict quality

standards

Our high-quality integrated production system has been set up to satisfy the wide range of customer requirements. We are equipped to accommodate both full-process orders from the manufacture of functional materials to final products, as well as half-process orders from the production of formulations to final products.

Production of

Functional Materials

-

Production of Oleo Fine Chemicals

Our unique patented technology utilizes the difference in the number of double bonds of unsaturated fatty acids to selectively extract particular omega-3 fatty acids such as EPA and DHA. By combining this with our advanced distillation technology, we are able to produce high-concentration reagent-level omega-3 fatty acids such as EPA and DHA.

-

Production of Extracts

Our technology for extracting, concentrating, and powdering various extracts (such as deodorization and enzyme processes) enables efficient commercialization of active ingredients. This proprietary technology improves both taste and stability.

Tablet Formulation

Development

BIZEN-Technology

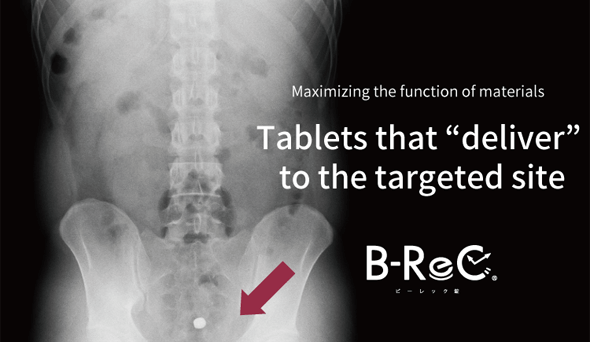

-

Tablets that deliver functional ingredients to the right place in the digestive tract and can be released at the right time

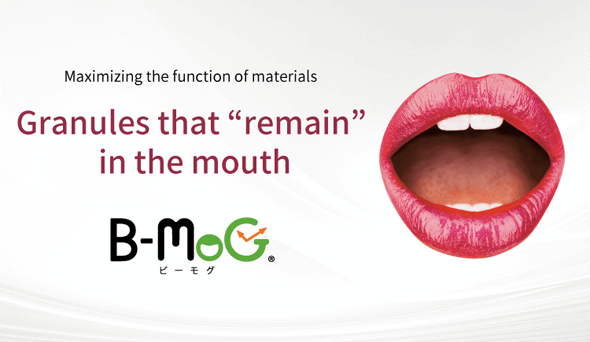

-

Technology that maximizes functionality by keeping the active ingredients in the mouth for a longer time. This solves the issues faced by conventional oral care products

-

Technology that enables the production of high-loaded tablets made from functional ingredients that are difficult to mix with high concentrations

Production of

Formulations

Compatible with various dosage forms from tablets to capsules

Compatible Dosage Forms

- ● Uncoated tablets, film-coated tablets (shellac, zein, yeast cell wall), sugar-coated tablets

- ● Granules

Spray granulation, extrusion granulation, high-speed agitation granulation - ● Hard capsules

- ● Soft capsules

- ● Drinks, jelly

Filling & Packaging

● Bottles, polyethylene containers, boxes (various transparent bottles), frosted bottles, etc.

● 3-way sealed packets

(aluminum, transparent film)

● Aluminum zipper bags (flat type, stand-up type)

● Stick packets

(17, 23, 25 (R-cut), 38 mm)

Quality Management

Our strict inspection standards and a thorough quality assurance system ensures we only deliver high-quality products with the highest level of safety and security. We strictly control the quality and safety of all processes from raw materials and raw material stocking to each manufacturing process, including the stage from completion of final products to shipping.

-

Raw materials

Raw material inspection

-

Pharmaceutical intermediates

Process inspection

-

Final product

Product inspection

-

After shipping

Product sample inspection

As part of our strict safety confirmation process before considering the commercialization of a product, we perform the following inspections on all raw materials.

- 1 Confirm that the raw materials are not included in the official list of components or materials that can only be used in licensed medical and pharmaceutical products (Pharmaceutical list).

- 2 Confirm that the raw materials are included in the official list of components or materials that are judged not to be pharmaceuticals unless labeled as having medicinal effects (Non-pharmaceutical list) or the raw materials are acknowledged that they have been consumed long enough to be safe in Japan.

- Health Food Products GMP

- On November 9, 2005, we obtained Good Manufacturing Practice (GMP) certification for dietary supplements from the Japan Health and Nutrition Food Association.

- ISO 9001

- As of July 18, 2006, the Japanese subsidiary of the British Standards Institution (BSI) certified that our quality management system is being operated effectively.

- FSSC 22000

- On January 24, 2022, we obtained the FSSC 22000 international standard for food safety management systems certification from the Japanese subsidiary of the British Standards Institution (BSI).

- EU-HACCP

- As of March 1, 2011, we have obtained Ministry of Health, Labour and Welfare certification for facilities handling fish and fishery products to be exported to the EU.

- FDA GMP in API Manufacturing

- We have passed the GMP inspection for the manufacturing of API pharmaceutical intermediates by the US Food and Drug Administration (FDA).